Exploring the Tactical Deployment of Small Pallets: Are They Right for You?

Rick LeBlanc

Editor, Reusable Packaging News

In a recent article, we explored why bigger pallets are better. The business case is obvious. With a bigger pallet, more product can be handled with every individual pallet move.

However, smaller can also be advantageous. Flying in and out of a smaller airport can help avoid the congestion and long lineups that often plague larger hubs, for example. And sticking with the flying metaphor, taking a smaller suitcase that you can carry onboard means eliminating the expense of a checked bag and the need to wait for it at the carousel after the flight has ended.

In this installment, we consider the flip side of the “Go big or go home” approach to pallets, looking at why small can be effective and profitable for tactical pallet deployments. As the old saying goes, “It’s not the size of the dog in the fight, it’s the size of the fight in the dog.” I’m not sure if that analogy exactly fits here, but my point is that a smaller footprint pallet can sometimes generate value that dramatically exceeds the loss of payload.

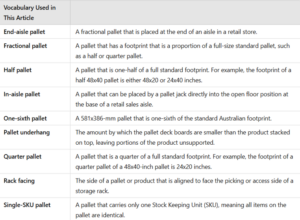

Usually, small pallets are not the standard size. Rather, they are deployed as a fractional size to meet particular needs. Let’s explore some of them. First, here is a vocabulary list for this article.

Small Pallet Vocabulary List

How Small Pallets Just Might Benefit Your Supply Chain

Deploying smaller pallets can add incremental value in several ways. Take a few moments to peruse these ideas to see if any of them have potential for your operation.

It fits your product better than the standard pallet

Sometimes, a standard pallet is just too big for the item being shipped and creates a lot of underutilized space. If you sending checkout line kiosks to retail stores that only fill up half the pallet, for example, you end up shippin a lot of air. When a load covers only part of the pallet surface, this is known as pallet underhang, and is usually an undesirable outcome. Switching to a smaller pallet can help better utilize the delivery truck and the retail back room.

It helps increase retail sales

Palletized floor displays, including end-aisle promotions, have been shown to increase spontaneous customer engagement and sales. Standard sized pallets are often used for display, but smaller pallets allow for more products to be featured. Half pallets (particularly 48×20-inch) are effective for end aisle displays.

It reduces touch labor at the warehouse and retail

Half and quarter pallets are often used for retail floor display where less inventory is required than for a full single-SKU pallet shipment. Such an approach significantly reduces touch labor at the warehouse compared to case picking a half or quarter pallet amount of cases, resulting in improved productivity. And at the store, display pallets can be directly positioned on the sales floor or in in-aisle locations, largely eliminating manual case stocking activity.

It is easier to navigate through congested spaces

Small pallets can be advantageous where doorway size is limited, and aisles are tight, such as in a convenience store, paint store, or older buildings. Some studies have found that using smaller pallets can help food service delivery drivers reduce the time at each stop, significantly reducing delivery costs.

It provides more facings at the warehouse or assembly line

When half pallets are not as wide as full pallets, more can be placed side by side in the same section of racking or assembly area. Where each holds a separate part or item, order pickers or assemblers require less travel time and enjoy greater efficiency.

It results in less product damage

A lot of damage occurs during the warehouse order picking and store delivery leg of the supply chain. Order-picking challenges can be daunting when building pallets with a variety of case sizes and rigidity, resulting in unstable loads and crushing. Because the cases stacked on the fractional display pallet are not individually handled as they flow through the distribution center, case picking damage is eliminated.

Get more goods on the truck

In some cases, there isn’t room for a final row of full standard pallets on the back of the truck, but there might be room for two half pallets. Using half pallets on the back where feasible can result in improved freight fill without the need for hand stacking to fill the void.

While larger pallets generally give you more bang for your material handling buck, there are can be compelling supply chain opportunities for small pallets. Take the time to see if they are a fit for you.